How wind ventilator works?

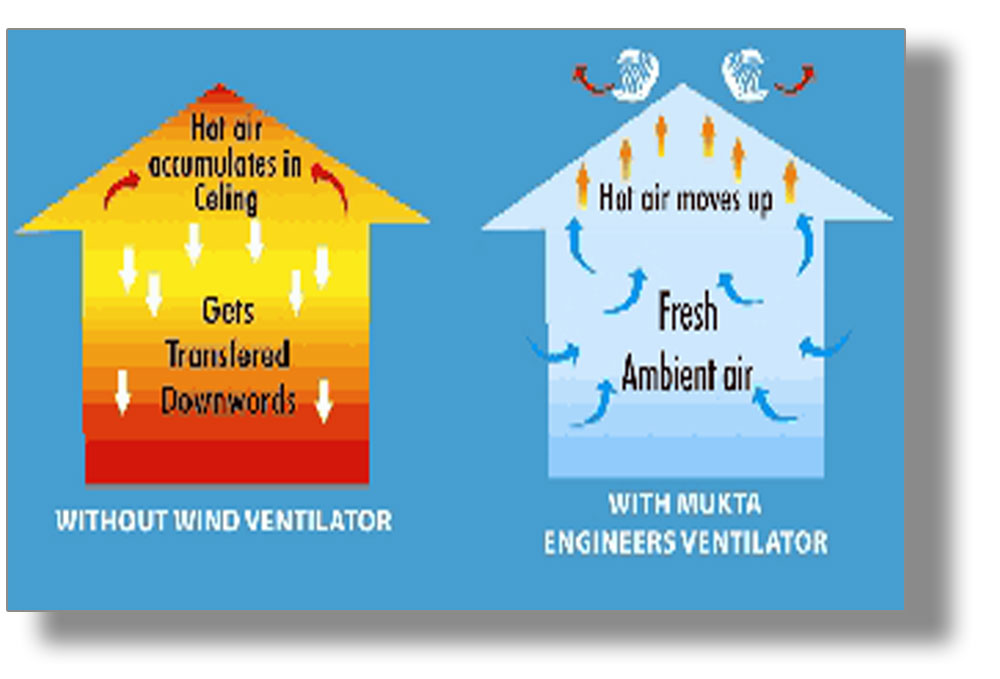

The turbine ventilator operates by utilising the velocity energy of the wind to induce air flow by centrifugal action The centrifugal force caused by the spinning vanes creates a region of low pressure area which draws air out theough the turbine. Air drawn out by the turbine is continuously replaced by fresh air from the outside.

The slightest breeze will cause the turbine ro spin and even after the breeze has stopped, the fly wheel effect of the rotor cage will use its stored energy to continuously remove air giving rise to ventilation. Suction is maintained even at low wind velocities. Hot air becomes lighter and accumulates at the center apex of the shed.

Motorised Exhaust Fans prove to be ineffective as they are unable to extract air from the apex of the Factory Shed. Mostly these fans are installed on walls and near windows and doors sucking most of the air from the outside and throwing it back again. The process and equipments continue to release odour, fumes even after factory shut down. These motorized fans cannot run 24 x 7 without being overheated and breaking down. Even if they do run 24 x 7 the cost of electricity would become prohibitive.

Features

Stainless steel top plate and bottom ring

Rigid roll formed curved aluminum vanes

Permenently lubricated sealed ZZ Bearings

No Maintenance - rust free

Rain proof rugged spider design

10 years performance waranty

Available in Aluminum and stainless steel

Advantages

No operating cost - runs on wind energy

Assured 24x7 Ventilation

80 % depreciation under section 32 of IT act

Replaces hot air humidity, stale air, smoke & gas fumes with fresh ambient air

Improves human comfort level and productivity